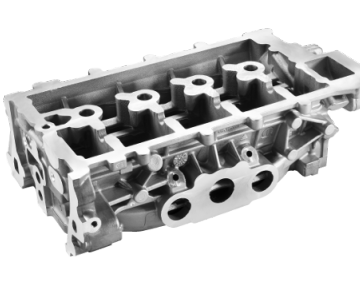

Firefly cylinder head

The Teksid Aluminum Carmagnola plant manufactures all the cylinder heads and cylinder blocks of the new STELLANTIS FILEFLY engine, for the EMEA market.

By the end of 2021 the installed capacity of the Teksid Aluminum – Carmagnola plant will reach 800.000 engines/year for a global investment of over 120 M€.

This production started in Carmagnola on April 2018 and is crucial technological step for the plant, that, with more that 9 millions cylinder head and cylinder blocks produced in the last 5 years, is considered one of the best aluminum foundries in Europe.

The FIREFLY cylinder head is produced with a gravity die casting technology. The cores are completely made of inorganic sand. This solution is fundamental in order to meet the requirements of FIREFLY engine, allowing precision, cleanliness of molds and emission-free castings. After being produced, then cylinder head is cut and deburred automatically before stepping into the T7 heat treatment. Later it undergoes the supercubing operations and the quality tests (water circuit, low and high pressure oil test). A final check of water and oil manifolds is done with Nano cameras.

And now, let’s take a look at the manufacturing of the FIREFLY cylinder head and to its cutting-edge production line.

10,0/14,3 KG

da 430x295x131 mm a 318x286x134 mm

AlSi7Cu0,5Mg / AlSiCu3 Mg

Go to plantsBetim, Brazil

Go to plantsCarmagnola plant 1, Italy